We offer a comprehensive online library featuring construction safety training courses and certifications for Spanish-speaking workers and contractors in the construction industry, the general industry, and the petroleum industry. As an OSHA-accepted training provider, these courses introduce workers to job-related health and safety issues covered by OSHA.

OSHA Safety Resources

You will find supplementary materials available for download by clicking the “Materials” tab on the menu located within the course player. Other reference materials are available from the OSHA website – please visit http://www.osha.gov/dte/outreach/.

- OSHA Outreach Trainer – Matt Luman – OSHAtrainer@360training.com

- General Industry OSHA Regulations – OSHA 29 CFR – Part 1910

- Construction OSHA Regulations – OSHA 29 CFR – Part 1926

FAQS

Are you OSHA Approved and are your courses compliant and approved?

OSHA does not approve or endorse products and therefore a course cannot be OSHA approved. OSHA only authorizes or accepts training providers. We offer an OSHA accepted program provided by 360training.com, an OSHA accepted provider.

OSHA does not approve or endorse products and therefore a course cannot be OSHA approved. OSHA only authorizes or accepts training providers. OSHA.com’s 10 and 30 hour OSHA Outreach Training courses are OSHA compliant, meet the OSHA 29 CFR 1910 and OSHA 29 CFR 1926 requirements

What are OSHA’s rules for online training?

For OSHA 10-hour/30-hour Outreach training programs, students must:

- Spend at least 600 minutes in a 10-hour training course and 1800 minutes in a 30-hour course.

- Complete a survey evaluating the course upon completion.

- Complete all course work (including survey) within three months for the 10-hour Outreach courses from the starting date.

- Complete all course work (including survey) within six months for the 30-hour Outreach courses from the starting date.

- Start the course within 12 months of registration.

- Pass all quizzes and the final exam with a score of 70% in three attempts or less.

Is there a time restriction on completing the OSHA 10-Hour and 30-Hour Outreach Courses?

Yes. You must complete the course within three months of the day you began the 10-hour courses. You must complete the course within six months of the day you began the 30-hour courses. You must begin your course within 12 months of registration.

Who should take a 10-hour or 30-hour safety training course?

The 10-hour course is intended for entry level workers. The 30-hour program is for workers with some safety responsibility.

What is covered in the 10-hour and 30-hour safety training courses?

The 10-hour safety training courses provide basic awareness training on the recognition, avoidance, abatement, and prevention of workplace hazards. The course also provides information regarding workers’ rights, employer responsibilities, and filing a complaint.

The 30-hour safety training courses provide a greater depth and variety of training on an expanded list of topics associated with workplace hazards in each industry. OSHA provides authorized trainers procedures for each industry program on the topic outlines for each industry.

HAZWOPER Training Levels

There are 3 levels for HAZWOPER training as listed in the OSHA 1910.120 regulations. Within these 3 levels are various job functions and training requirements. Each of these levels offer HAZWOPER certification for the different job functions.

Level 1. Emergency Response

- First Responder

- HAZMAT Technician

- HAZMAT Specialist

- Incident Commander

Level 2. Cleanup of Contaminated Hazardous Waste Sites

- 40 hour HAZWOPER Site Worker

- 24 hour HAZWOPER Site Worker

- HAZWOPER Supervisor

Level 3. Treatment, Storage, and Disposal (TSD) of Hazardous Waste

- 24 hour HAZWOPER Site Worker

Overview of Federal OSHA HAZWOPER Training Requirements

| Operation | Level | Initial Training |

Annual Refresher Training

|

|

|---|---|---|---|---|

| Site Clean-Up Operations | ||||

| Site Worker | 40-hours with three days of field experience | 8-hours | (e)(3)(i) | |

| Occasional Site Worker | 24-hours with one day of field experience | 8-hours | ||

| Manager or Supervisor | 40-hours with three days of field experience + 8 hours of supervisor training | 8-hours | ||

| TSD Facilities | ||||

| Site Worker | 24-hours | 8-hours | (p)(7)(i) | |

| Emergency Response | ||||

| First Responder Awareness | Competency-based; no hourly requirement | Competency-based; no hourly requirement | (q)(6)(i) & (q)(8) | |

| First Responder Operations | 8-Hours | Competency-based; no hourly requirement | (q)(6)(ii) &(q)(8) | |

| HAZMAT Technician | 24-hours | Competency-based; no hourly requirement | (q)(6)(iii) &(q)(8) | |

| HAZMAT Specialist | Technician Level + Competencies | Competency-based; no hourly requirement | (q)(6)(iv) &(q)(8) | |

| Incident Commander | 24 hours equal to first responder operations + Competencies | Competency-based; no hourly requirement | (q)(6)(v) &(q)(8) |

Note: OSHA Plan States may have different HAZWOPER training requirements. These requirements must be at least as stringent as the Federal OSHA requirements.

RCRA EPA Resources

More About RCRA 8hr Refresher Training Courses

Congress enacted the RCRA to address the increasing problems the nation faced from its growing volume of municipal and industrial waste. RCRA, which amended the Solid Waste Disposal Act of 1965, set national goals for:

- Protecting human health and the environment from the potential hazards of waste disposal.

- Conserving energy and natural resources.

- Reducing the amount of waste generated.

- Ensuring that wastes are managed in an environmentally-sound manner.

RCRA in Day to Day Operations – 2hrs

Resource Conservation and Recovery Act (RCRA) is designed to track hazardous waste from cradle to grave. Under RCRA, hazardous waste generators are the first link in the cradle-to-grave hazardous waste management system.

This RCRA Training course covers RCRA regulations relating to generators, containers, and hazardous waste management plan (HWMP). The goal of HWMP is to handle hazardous waste in a safe, efficient, and environmentally sound manner and to comply with RCRA regulations.

RCRA: What the Law Requires – 4hrs

This RCRA Training course explains the history of the Resource Conservation and Recovery Act (RCRA), its structure and its key elements that provide the framework for the U.S. Environmental Protection Agency’s (EPA) comprehensive waste management program. The course discusses the specific requirements of various types of facilities that treat, store, transport or dispose of hazardous waste.

Resource Conservation and Recovery Act (RCRA) Laws and Regulations

Resource Conservation and Recovery Act (RCRA) Orientation Manual

This manual provides introductory information on the solid and hazardous waste management programs under the Resource Conservation and Recovery Act (RCRA). Designed for EPA and state staff, members of the regulated community, and the general public who wish to better understand RCRA, this document constitutes a review of the RCRA program and is not a substitute for RCRA or its implementing regulations. The manual comprises seven sections plus appendices:

This manual provides introductory information on the solid and hazardous waste management programs under the Resource Conservation and Recovery Act (RCRA). Designed for EPA and state staff, members of the regulated community, and the general public who wish to better understand RCRA, this document constitutes a review of the RCRA program and is not a substitute for RCRA or its implementing regulations. The manual comprises seven sections plus appendices:

- Introduction to the Resource Conservation and Recovery Act;

- Managing Solid Waste – RCRA Subtitle D;

- Managing Hazardous Waste – RCRA Subtitle C;

- Moving Forward: Materials Management and Resource Recovery;

- Miscellaneous Statutory Provisions;

- RCRA and its Relationship to Other Environmental Statutes; and

- Public Participation in the RCRA Program.

- Resource Conservation and Recovery Act Orientation Manual 2014 (PDF)

(242 pp, 8 MB, October 2014, EPA530-F-11-003)

RCRA Overview

RCRA Regulations

RCRA Tools and Resources

RCRA Resources for State Officials

RCRA Training Modules

The EPA developed training modules that provide an overview of hazardous waste regulatory topics. These courses are not intended to serve as comprehensive sources of regulatory information.

- Air Emission Standards

- Boilers and Industrial Furnaces

- Closure/Post-Closure

- Containers

- Containment Buildings

- Corrective Action

- Definition of Solid Waste and Hazardous Waste Recycling

- Drip Pads

- Enforcement and Compliance

- Exclusions

- Financial Assurance

- Generators

- Groundwater Monitoring

- Hazardous Waste Identification

- Hazardous Waste Incinerators

- Land Disposal Restrictions

- Land Disposal Units

- Miscellaneous and Other Units

- Municipal Solid Waste Disposal Facility Criteria

- Permits and Interim Status

- Petitions, Delistings, and Variances

- Solid Waste Programs

- State Programs

- Statutory Overview

- Treatment, Storage, and Disposal Facility Criteria

- Tanks

- Transporters

- Used Oil

- Universal Waste

New Miner Training Resources

Training Requirements

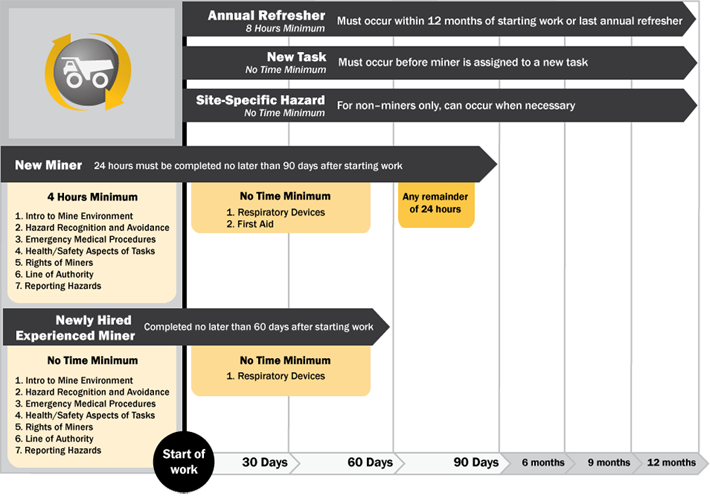

The timeline below should help clarify the minimum MSHA Part 46 training requirements. Prior to taking any of these courses, you should confirm which training is required by your employer and that your employer accepts this training as part of an approved training plan.

While these regulations refer to “Miners,” MSHA requires that mining contractors who perform work at surface mines on a regular basis to have all of the same training as a surface miner.

New Miner Training (30 CFR Part 46.5)

- A person beginning employment as a miner or an independent contractor performing work at a mine is considered a New Miner.

- New Miners require a minimum of 24 hours of training in 9 subjects within their first 90 days of employment.

Ref: 360training.com

Compliance Help

- MSHA Part 46 Compliance Guide – Here’s a link to MSHA’s online guide for Part 46.

- http://www.msha.gov/training/part46/compguide/46compguide.htm

- Mine Safety and Help Network – Provides MSHA help from a legal perspective.

- http://mshahelp.com/

Training Plan Resources

Our training partner offers Training Plans in a downloadable format to help organize your employee training.

- Download Training Plan Templates – Here are downloads of our Training Plans in Microsoft Excel/RTF format based on an MSHA templates and guidelines.

- Coversheet

- New Miner

- Newly Hired Experienced Miner

- Annual Refresher

- New Task

- Site-Specific Hazards

- Link to MSHA’s Training Plan Guide – Here’s a PDF of MSHA’s Training Plan Guide.

- http://www.msha.gov/TRAINING/PART46/PT46SKMODEL.pdf

- Link to MSHA Online Training Plan Advisor – MSHA provides an online Training Plan creation tool that also allows you to submit the finished output online. Be prepared. It may take a while to get through.

- http://www.dol.gov/elaws/msha_train.htm

Record of Training Resources

- Download Template – Here’s a blank Record of Training template in Microsoft Excel format based on an MSHA template.

- Record of Training Template

Introduction to Molds

Molds produce and release millions of spores small enough to be air-, water-, or insect-borne. They can also produce toxic agents known as mycotoxins. Spores and mycotoxins can have negative effects on human health.

For those people who are affected by mold exposures there can be a wide variation in how they react. People at greatest risk of health effects are individuals with allergies, asthma, sinusitis, or other respiratory conditions, as well as infants and children, elderly people, and pregnant women. In addition, individuals with a weakened immune system are at risk.

Reference: Occupational Safety & Health Administration (OSHA) – Molds

EPA Training – Mold Course

Introduction to Mold and Mold Remediation for Environmental and Public Health Professionals (PDF). Environmental Protection Agency (EPA) Mold Web Course. Gives specific recommendations for personal protective equipment (PPE) when cleaning mold.

- Mold Course Chapter 1: Introduction to Molds

- Mold Course Chapter 2: Why and Where Mold Grows

- Mold Course Chapter 3: Finding Mold and Moisture

- Mold Course Chapter 4: General Remediation Issues

- Mold Course Chapter 5: Large Areas and Other Special Concerns

- Mold Course Chapter 6: Containment and Personal Protective Equipment (PPE)

- Mold Course Chapter 7: Evaluating the Remediation

- Mold Course Chapter 8: Communicating with the Building Occupants

- Mold Course Chapter 9: Prevention

Also available:

OSHA Resources and References

- Bardana, E. Indoor air quality and health: Does fungal contamination play a significant role? Immunological and Allergy Clin N Am. (23) 2003: 291-309

- 29 CFR 1910.134, Respiratory protection. OSHA Standard.

- A Brief Guide to Mold in the Workplace. OSHA Safety and Health Information Bulletin (SHIB), (2003).

- Fungi Hazards and Flood Cleanup [3 KB PDF*, 2 pages]. OSHA Fact Sheet, (2005).

- Mold [22 KB PDF*, 2 pages]. OSHA Fact Sheet, (2005).

- Mold. OSHA Safety and Health Topics Page.

- Storm/Flood and Hurricane Response. National Institute for Occupational Safety and Health (NIOSH) Workplace Safety and Health Topic.

- Mold Prevention Strategies and Possible Health Effects in the Aftermath of Hurricanes and Major Floods. Centers for Disease Control and Prevention (CDC), (2006). (Also available in: Mortality and Morbidity Weekly Report, June 9, 2006/55(RR08);1-27)

- Guidelines for the Protection and Training of Workers Engaged in Maintenance and Remediation Work Associated with Mold [448 KB PDF, 43 pages]. National Clearinghouse for Worker Safety and Health Training, (2005).

- Mold Remediation in Schools and Commercial Buildings. Environmental Protection Agency (EPA), (2001, March).

- Guidelines on Assessment and Remediation of Fungi in Indoor Environments [71 KB PDF, 25 pages]. New York City Department of Health and Mental Hygiene, (2008).

- Respirator Selection Logic 2004. Centers for Disease Control and Prevention (CDC), (2004, October).

National Environmental Policy Act (NEPA)

The National Environmental Policy Act (NEPA) is a United States environmental law that established a U.S. national policy promoting the enhancement of the environment and also established the President’s Council on Environmental Quality (CEQ). The essential purpose of NEPA is to ensure that environmental factors are weighted equally when compared to other factors in the decision making process undertaken by federal agencies.

National Institute for Occupational Safety and Health (NIOSH)

DHHS (NIOSH) Publication Number 2013-102

NIOSH Alert: Preventing Occupational Respiratory Disease from Exposures Caused by Dampness in Office Buildings, Schools, and Other Nonindustrial Buildings

The guidance includes a building inspection checklist and may be of interest to people working in office buildings, schools and other nonindustrial buildings.

Reference: http://www.cdc.gov/niosh/docs/2013-102/

EPA Compliance Regulations

- CAA – Clean Air Act http://www.epa.gov/air/caa

- CWA – Clean Water Act http://www.epa.gov/regulations/laws/cwa.html

- RCRA – Resource Conservation & Recovery Act http://www.epa.gov/regulations/laws/rcra.html

- EPCRA – Emergency Planning & Community Right-to-Know http://www.epa.gov/osweroe1/content/epcra

- TSCA – Toxic Substance Control Act http://www.epa.gov/lawsregs/laws/tsca.html

- CERCLA – Comprehensive Environmental Response Compensation & Liability Act http://www.epa.gov/superfund/policy/cercla.htm

- IICRC – Institute of Inspection, Cleaning & Restoration Certifications http://www.iicrc.org/what-does-certified-mold-inspector-training-offer-a-33.html

NAMP Standards for Conduct and Ethics

To promote and protect the Mold Detection and Remediation Industry, and members of the National Association of Mold Professionals, NAMP has developed the following Standards for Conduct and Ethics to be followed by its members:

- The Mold Professional shall uphold the honor and dignity of this profession and avoid association with any enterprise of questionable character or apparent conflict of interest.

- The Mold Professional shall protect and promote the interests of the client to the best of the Mold Professional’s ability and knowledge, recognizing that the client has placed its trust and confidence in the Mold Professional.

- The Mold Professional shall always endeavor to maintain and increase his/her level of knowledge regarding new developments in the field.

- The Mold Professional shall conduct his/her business in a manner that will assure the client of the Mold Professional’s independence from outside influence and interest, which would compromise the Mold Professional’s ability to render a fair and impartial opinion, regarding any inspection performed.

- The Mold Professional shall not accept compensation from more than one interested party for the same service on the same property without the consent of all interested parties.

- The Mold Professional shall promptly disclose to the client any interest in any other business which may effect the client, the quality, or the result of the inspection or remediation.

- The Mold Professional shall not knowingly use the inspection or remediation process to obtain work in another field.

- The Mold Professional shall make every effort to uphold, maintain and improve the professional practice, integrity and reputation of The National Association of Mold Professionals.

Introduction to Asbestos Hazards

Workers can be exposed to asbestos fibers during activities that disturb asbestos-containing materials including during home or building construction, renovation or demolition.

OSHA is responsible for establishing standards to protect the health and safety of workers who may be exposed to asbestos in the work place. Through EPA’s regulatory authority under the Toxic Substances Control Act (TSCA) (PDF) (35 pp, 280 K, About PDF), the EPA is responsible for protecting state and local employees who may be exposed to asbestos from their jobs in states without an OSHA-approved state occupational safety and health plan who may be exposed to asbestos from their jobs.

EPA – Learn more about Asbestos

29 CFR 1926.1101 – OSHA’s Asbestos Standard for the Construction Industry

Select a slide by clicking on the associated thumbnail, or download the entire PowerPoint Presentation

[PPT* – 397 KB].

EPA Accredited Training Requirements

The Environmental Protection Agency (EPA) also provides requirements for asbestos inspectors and workers. Organizations that offer training courses must meet EPA guidelines.

Training for asbestos professionals is required under the EPA Asbestos Model Accreditation Plan (MAP) which EPA issued under the Asbestos Hazard Emergency Response Act of 1986 (AHERA). The MAP requires the use of trained and accredited asbestos professionals when conducting asbestos inspections or designing or conducting response actions at schools and public and commercial buildings. It provides guidance to states on the minimum training requirements for accrediting asbestos professionals. State training programs must be at least as stringent as the MAP. The MAP established five required training disciplines:

- Worker

- Contractor/supervisor

- Inspector

- Management planner, and

- Project designer

In addition, one training discipline (project monitor) is recommended.

In addition to this initial training, asbestos professionals must take annual refresher training. The EPA determined that online training can satisfy this requirement in lieu of in-person training.

State Asbestos Contacts

Many states administer an asbestos program and your state department of environmental protection or health will be the best place to address asbestos questions that can not otherwise be answered with the information on this website. The states will also have the most up-to-date list of training courses for asbestos professionals.

Click here to view EPA States List of Contacts

Additional OSHA Training Materials

- 29 CFR 1926.1101 – OSHA’s Asbestos Standard for the Construction Industry [PPT*]. OSHA Slide Presentation, 80 slides.

- Significant Changes in the Asbestos Standard for Construction 29 CFR 1926.1101. OSHA.

- Significant Changes in the Asbestos Standard for General Industry, 1910.1001 (through June 29, 1995). OSHA.

Additional Resources

- Asbestos. OSHA Safety and Health Topic Page.

Asbestos Laws and Regulations

This page provides a listing of the laws and regulations pertaining to asbestos implemented by the EPA and certain other federal agencies. See more information on U.S. Federal Bans on Asbestos.

Federal and State Links

USDOL Occupational Safety and Health Administration (OSHA) works to prevent injuries and protect the health of workers.

- US DOL Occupational Safety and Health Administration (OSHA), including the laws, regulations, and services.

- US DOL Employment Law Guide – Occupational Safety and Health

- Bureau of Labor Statistics

- Environmental Protection Agency

- National Institute for Occupational Safety and Health (NIOSH)

- Mine Safety and Health Administration (MSHA)

- National Transportation Safety Board (NTSB)

- Centers for Disease Control and Prevention, Injury and Violence Prevention and Control

- Children’s Safety Network

- Federal Emergency Management Agency

- National Highway Traffic Safety Administration

- National Safety Council

- Safe States

Chemical Information

- OSHA Occupational Chemical Database

- Toxnet – National Library of Medicine Toxicology Data Network

- Agency for Toxic Substances and Disease Registry (ATSDR)

- NIOSH Pocket Guide to Chemical Hazards

MSDS Sites

Nonprofit Organizations and Standards

- American Red Cross

- Electrical Safety Foundation

- National Safety Council

- American National Standards Institute (ANSI)

- National Fire Prevention Association

- Industrial Truck Standards Development Foundation

- American Welding Society

Training

- The Pacific Northwest OSHA Education Center (Seattle)

- Boise State University Center for Excellence for Environmental Health and Safety

- Rocky Mountain Center for Occupational and Environmental Health

- OSHA E-Tools (Web-Based Training Tools)

Safety Professional Organizations

- Snake River Chapter of the American Society of Safety Engineers

- American Board of Industrial Hygiene

- Board of Certified Safety Professionals

Private Sites

Other Safety Information